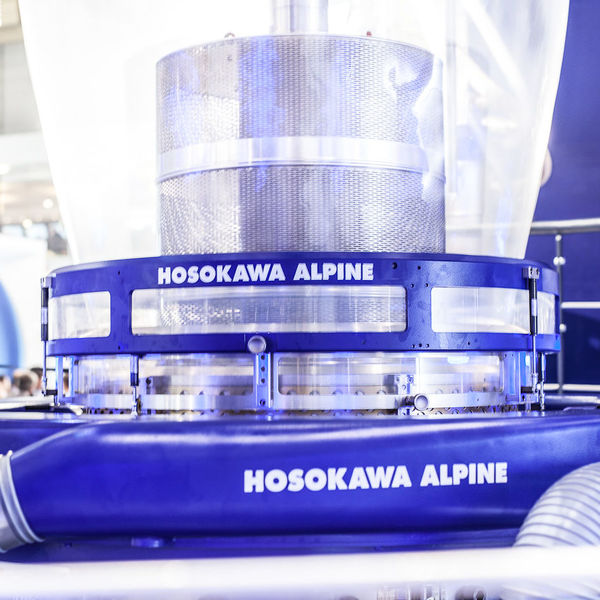

For Powder & Particle Processing

Spares & Repairs

Process Management

Remote Service

Safety Check

Find out more

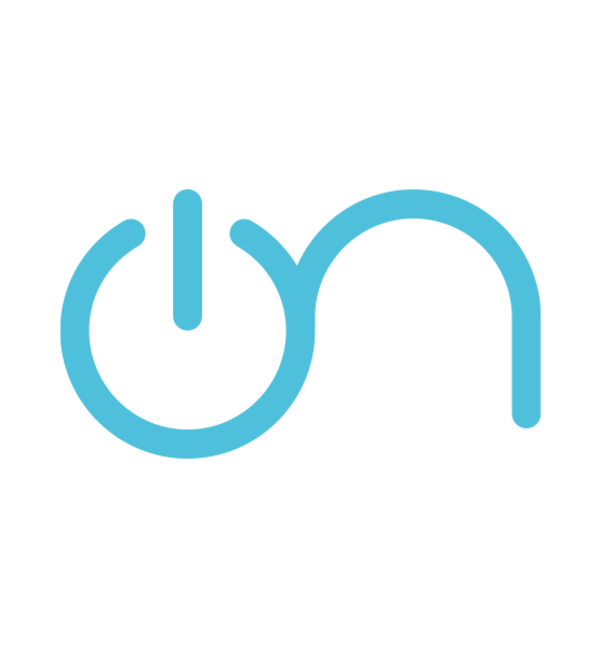

For your blown film line

Spares & Repairs

Cleaning of die Heads

Remote-Service/eSupport

Find out more

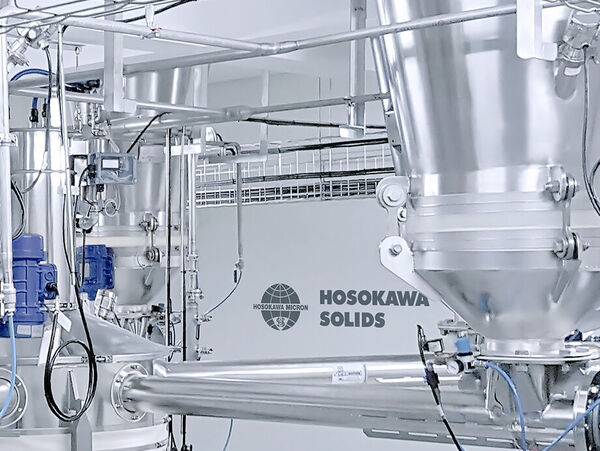

Hosokawa Solids at Hosokawa Alpine

Your bulk solids. Our solution.Pneumatic conveying, weighing and metering technology as well as complete silo systems: Since 2020, Hosokawa Solids and its components and systems have been part of the Hosokawa Alpine Group. Now you can also find the complete range of Hosokawa Solids on our website.