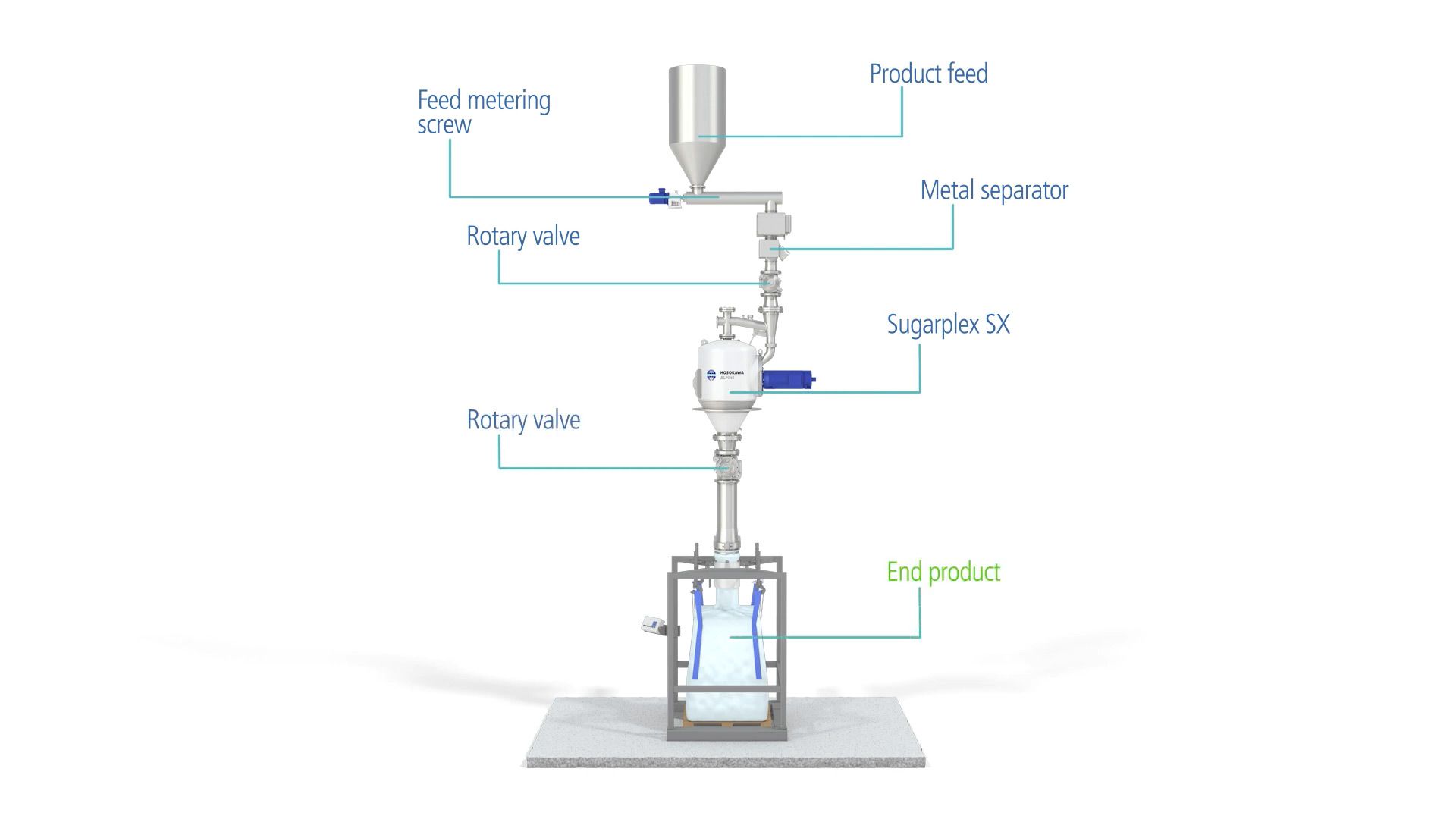

Due to their diversity, different sweeteners are processed in very different ways. The demands placed on size reduction technology range from high throughput rates for household sugar and uniform particle sizes for sugar blends to sugar conditioning for shelf-stable icing sugar.

In addition, monosaccharides and polysaccharides (dextrose, glucose, sucrose, maltose, galactose and fructose) with particle sizes < 200 µm pose a high explosion risk, meaning that machines and systems need to be explosion-protected in accordance with international directives and standards.

We have taken on these challenges: We are revolutionising the sugar milling market with easy-to-integrate, explosion-protected system concepts that we custom-design according to your preferences and requirements.

![[Translate to English:] ACM](/fileadmin/_processed_/e/7/csm_ACM-40-CL_7a8abe7599.png)