PROCESS CONSULTING

Your experts in the field of mechanical process engineeringAre you planning a new process or are you just about to come up with a new product idea and need support? Process Consulting helps you with the system planning and implementation of your ideas in the fields of size reduction, classifying, compacting or agglomeration of powders, granules and bulk materials. The result? A solid foundation for decision-making, based on the wealth of expertise offered by the Hosokawa Group and an investment at the outset that helps you to make big savings throughout the process.

Material development: Material with optimal properties

Specifically tailored to your productWhat properties does a material need so that you can produce a product according to your wishes? Our experts develop individually adapted materials that meet your requirements exactly. In the development process, we use the latest technologies and methods.

Process development: The perfect powder process

Developed for your specific needsIn a custom-fit powder process, many parts come together to form a large whole: from various tests and substance balances to cost analyses and decision matrices to process transfer to other applications, locations or manufacturers. Process Consulting works with you to develop your custom-fit powder process, which we will be happy to implement with you later.

Your advantages with Process Consulting

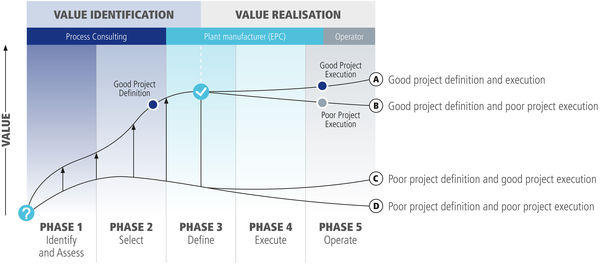

Support and consulting from experienced development partnersCreate value right from the start

Let's pave the way for your success!

Process Consulting - that's how it works

Transform your idea into an optimal investmentYour requirements: what is the task?

As the first step, we put your idea in concrete terms and define the task. To do this, we look at your idea holistically, taking into account the special properties of your bulk material or system. In a feasibility analysis, we analyse the current situation and your needs. This includes component or system tests, comparisons of different technologies and your time to market. On this basis of the findings, we draw up a specification document that sets out all the requirements for the process and the general conditions (e.g. ATEX or building). At the end of this step, you will receive a rough implementation concept and cost estimate. This defines the main components of your process and records them in a rough process flow diagram.

Your options: what are the alternatives?

In the next step, we develop several solutions for your individual requirements. This includes tests to check technical feasibility, initial process flow diagrams and a cost analysis in terms of OPEX and CAPEX. At the end, you will receive various process proposals and an evaluation of these alternatives.

Your solution/decision: how are your options evaluated?

In the last step, we take a closer look at the different options so that you can make the best decision in the end. This includes risk analyses and decision matrixes, flow diagrams and a 3D visualisation with your main process components and building structures. Once this is finished, you will have found the process that best meets your requirements and a solid foundation for your further business plan. It is up to you whether you implement this process with a different manufacturer of your choice or once again rely on Hosokawa Alpine's know-how and experience.

“From the very beginning, our collaboration with the Process Consulting team of Hosokawa Alpine was constructive and solution-oriented. Their technical competence and many years of experience were obvious and strengthened our confidence in having made the right decision”.

Michael Österreicher, CFO of Nobelmin GmbH