Particle design

Manufacture of new and functional materialsBehind the idea of particle design is the wish for improved material properties. Whereas in the past, the aim was generally the production of ever finer powders, today the focus is on equipping particles with specific properties. These properties can be mechanical, optical, electric or chemical I nature. The efforts in this direction have opened up extremely interesting possibilities especially in the fields of pharmaceuticals, cosmetics, battery/secondary battery manufacture, metallurgy and fuel cell development. Besides the pure application, however, certain aspects of handling the extremely fine products need to be considered. Assuming a suitable machine design, the well-known unit operations such as comminution, dispersion, rounding, coating and agglomeration can also be carried out on a nano scale in order to achieve the desired product properties.

Particle design: technologies

- Coating: Fine particles are permanently fused without the need for binders onto the surface of the base material by means of a mechanical process: Mechanofusion. Systems: AMS, Nobilta.

- Dispersion/micro-mixing: Optimum mixing quality from the micrometre to the nanometer range. Systems: Nobilta.

- Rounding: Better flow properties and higher packing density. Systems: AMS, Faculty, Alpine Particle Rounder APR for natural graphite and classifier mill Zirkoplex ZPS for synthetic graphite.

- Agglomeration: Granulation (spherical particles with shell-type structure) or agglomeration of primary particles (raspberry-like structure). Improved handling, additional coating. Systems: Agglomaster.

Application examples

Lithium cobaltate / carbon black

for rechargeable batteriesCarbon black is fused onto the surface of the lithium cobaltate in a Mechanofusion process. The machine of choice for this process is the Nobilta. Originally in agglomerate form, the carbon black is dispersed in this process and fuses in a thin layer onto the base material. The following positive properties result: improved, conductivity of the electrodes. No agglomerates in the bulk material, low viscosity of the suspension during electrode manufacture.

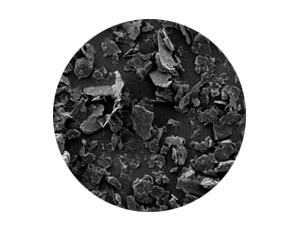

Graphite

Higher tap density for a higher storage capacityGraphite flakes are rounded by mechanical effects and the bulk material is simultaneously dedusted. There are two machines for this process - depending on whether synthetic graphite or natural graphite is to be rounded. The Zirkoplex ZPS classifier mill is the first choice for synthetic graphite, and the Alpine Particle Rounder APR was developed for the spheroidisation of natural graphite. Here, the natural graphite is pre-ground on a classifier mill. Subsequently, batchwise rounding with downstream classifying takes place. As a result of the rounder particle and the smoother surface, the bulk density of the material is much higher. The capacity of batteries is higher, in accordance with the bulk density.

Pharma products (carrier material/active substance)

For even dosingActive substance particles are dispersed and fixed mechanically in a thin layer onto the carrier particle. In the case of pharmaceutical active substances, the machine of choice is the AMS system. The flow properties of the composite are extremely good and promote uniform metering of the active substance. Resorption of the active substance is simultaneously accelerated, because the active substance is available over a very large surface area.

Nickel oxide/YSZ

for fuel cellsNickel oxide and yttrium-stabilised zirconia (YSZ) are both available in a finely dispersed form. Both materials have a strong tendency towards agglomeratin. What is important in this application is an extremely intricate bond of the materials in the micrometer range, whoch then makes it possible to significantly reduce the operating temperature of the SOFC (Solid Oxide Fuel Cell)- The best results by far have been achieved here with the Nanocular system, in addition to the Mechanofusion process, a plasma acts upon the materials.