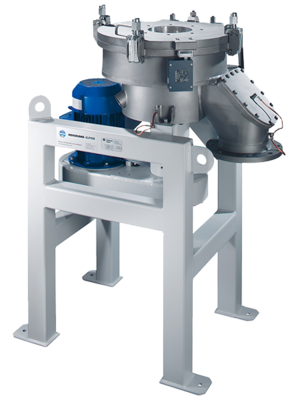

The feed material is dispersed by the classifying wheel and transported through the same by the classifying air. The dust entrained in the air is transported through the support wheel and discharged via the fines discharge. The coarse product is rejected by the classifying wheel and conveyed to the coarse material discharge. The product routing is designed such that no back-mixing can occur and a high quality of dust removal is ensured. The special configuration with the support wheel is patented; it permits optimum access for quick and thorough cleaning at minimum downtime.

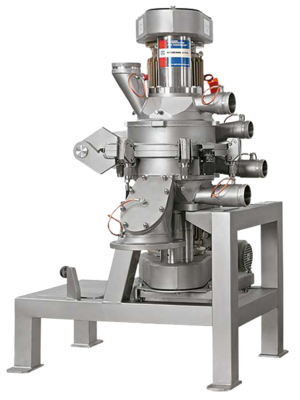

Protected by additional patents, the TTSP classifier is a refinement of the TSP classifier, primarily with the aim of improving the precision of cut even further by means of two consecutive classifying stages. At the same product loading of the classifying air, the TTSP classifier achieves a much higher precision of cut than the TSP, or at a constant coarse product quality, achieves a higher loading factor. This makes it possible to almost treble the throughput in comparison with the TSP.

Dust removal from toner and powder coatings containing titanium dioxide

The demands made of the end-product quality in toner processing are so high that particle counters (Coulter Counter) are employed for quality control. Specification of the dedusted coarse material is given in number%, whereby the specification generally permits 3-10 number% < 5 µm.

The use and manufacture of chemical substances, including titanium dioxide, are subject to strict registration, testing and approval processes. Legal requirements ensure that these chemicals are harmless to health and the environment in their intended uses. The critical fine fraction of <10 µm is <1% after classifing with the TSP classifier. The backmixing-free product flow ensures a high quality of dedusting. The hinged housing enables optimal accessibility for quick, thorough cleaning and significantly minimizes downtimes.

Design:

- Stainless steel

- Polished, Ra 0.8 µm

- Three-fraction classification for special toner applications, to this end, the classifier is equipped with a special classifying wheel in the 2nd stage, and the classifying system is laid out for the collection of the 3 fractions toner powder, dust and coarse particles