Further developments for new requirements

Hosokawa Alpine Aktiengesellschaft has vast experience and know-how in the field of food processing. The long-established German company installed production lines worldwide in the fine grinding of Soybean-Processing-Products like full-fat soy, extruded-, extracted-, roasted- and Soy Protein Concentrate (SPC) flakes/grits.

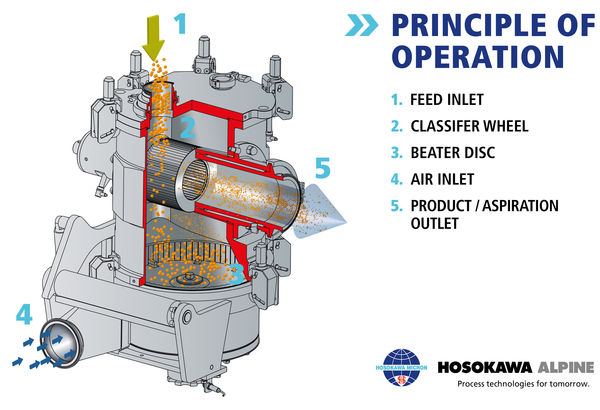

Contraplex CW II – a new dimension in grinding quality

The CW II model is the latest version of the tried and trusted design, which has been optimized specially to suit customer requirements. This machine is mainly used in grinding foods and in manufacturing polymer powder. Hosokawa Alpine optimized the Contraplex® CW wide chamber mill based on an intensive customer survey. In developing the new generation of the CW II type, the engineers took into account the increased requirements from the user's point of view. In order to markedly improve cleaning in terms of duration and accessibility, the CW II has been equipped with a larger door aperture and wider door opening angle. Cleaning of the scavenging air ducts in particular has been optimized from a GMP standpoint.

Hosokawa Alpine technology center makes individual requests possible

The main concern for Farmesa was to have reliable, flexible and safe machinery. All organic products below 500 µm have the tendency to explode. Farmesa was eager to get a safe system and explosion protected system to protect their operators and their investment. As well the flexibility of the machinery to fulfill the changing market requirements was for Farmesa a reason for such investment.

Due to the natural variations of food products, tests at the Hosokawa Alpine technology center are advisable. With more than 3,000 sqm and more than 65 machines and complete systems Hosokawa Alpine in Augsburg has one of the largest test centers for wet and dry powder processing in the world.