Hosokawa Alpine has decades of experience in the development and manufacture of high-performance cutting systems for various materials and industries. The Rotoplex granulator as an all-rounder has been continuously developed and innovatively improved. For example, it can be used in the food industry for the pre-comminution of spices before grinding, but also for the rework of snack products or for the comminution of gelatine. This technology was able to convince the Boletus company.

Boletus grinds herbs & medicinal plants

Where herbs go under the knifeWe used to deliver our herbs whole. With the Rotoplex, we can now meet our customers’ demands for semi-finished products such as cut herbs and plants, and offer support in processing them into high-quality finished plant products.

Salko Pašić, Managing Director of Boletus

‘Boletus’ is not only the Latin name of the porcini mushroom, but also the name of the company from Bosnia and Herzegovina founded in 2000. The company has over 100 different wild plants and herbs in its portfolio, which are its base products for producing herbal medicines, foods and teas as well as natural cosmetics. To be able to offer its partners and customers from all over Europe even higher quality products, Boletus began looking for a machine solution in 2019 for cutting goods, and found exactly what it was looking for during a visit to Hosokawa Alpine in Augsburg.

Customised design for the highest quality

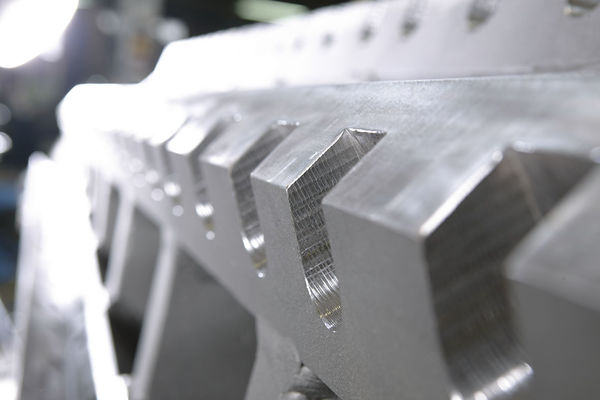

Boletus opted for a Rotoplex Ro 28/40 granulator with connected sieving machine. It combines a compact and modular design with powerful components. The rotor variants, motorisation and material feed unit were customised and manufactured for the customer. A simple exchange of the insertable sieves with different hole sizes and designs, allows for a quick and flexible response to the different feed materials. Based on a building sketch, the Hosokawa Alpine team was able to adjust the system to the exact spatial conditions on site as well as the various herbs and fibrous natural materials to be processed. The mill rotor and the housing of the Rotoplex series are made of solid nodular cast iron, which provides additional stability. To guarantee the purity of the food produced, a special shaft bearing also prevents product from entering the bearing and, conversely, excess grease from entering the grinding chamber. The cut product is separated using cyclones and brought to the desired fraction with the help of the sieving machine. When cleaning the machine or changing the knives, the sieve basket can simply be folded down.

The mill is characterised by its cross-scissor cut, which is achieved with three rows of rotor knives and two rows of stator knives. This means that very little fines are produced – which is important for the customer as it produces products such as herbal teas. The fine dust would clog the pores of the tea bag, which is why our mill is an especially reliable solution for these requirements.

Nicole Dünzer, Sales Manager at Hosokawa Alpine.

Setting new standards for customers

The Rotoplex Ro 28/40 achieves up to 200 kg throughput per hour with the drive of up to 15 kW. After completion of the process, some of the wild herbs and medicinal plants are dried, while others are deep-frozen or preserved in brine before being shipped all over Europe. Since May 2019, the system has operating seamlessly at the customer’s location in Hađžići, and they are very satisfied with the new operating procedure. “We can offer our existing customers our herbs and plants as high-quality cuttings, thereby saving them a production step. At the same time, this has also made us attractive to a whole new group of customers who only buy cut goods and who are now able to purchase them through us,” explains Salko Pašić. In fact, customer feedback is so good and demand is so high that he is already thinking about expanding his capacities – something Nicole Dünzer is certainly pleased about. “It’s always great to see how we can offer support to our customers with our solutions. The cooperation with the Boletus team was very pleasant from the beginning and we are pleased that they were able to expand to new market segments thanks to our Rotoplex.”