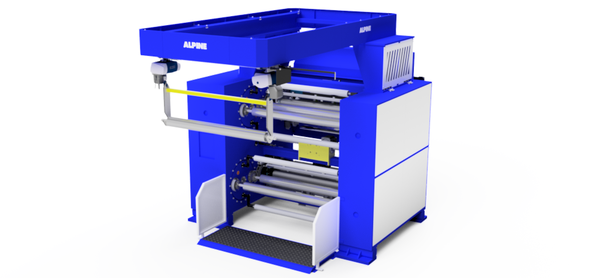

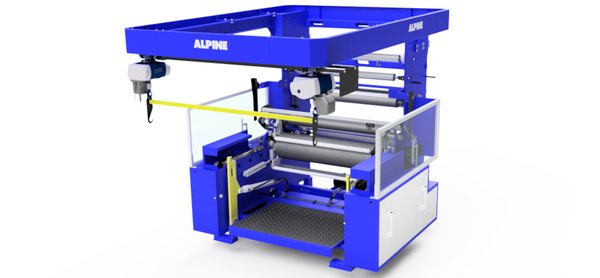

What would be an elaborately produced film without the appropriate winding technology? For more than 70 years, the Alpine subsidiary HOSOKAWA KOLB has been developing solutions for perfect film rolls:

- experience gained from more than 2,500 produced winding machines

- close cooperation with experts from blown film extrusion

- product portfolio that offers the optimum winder for every type of film