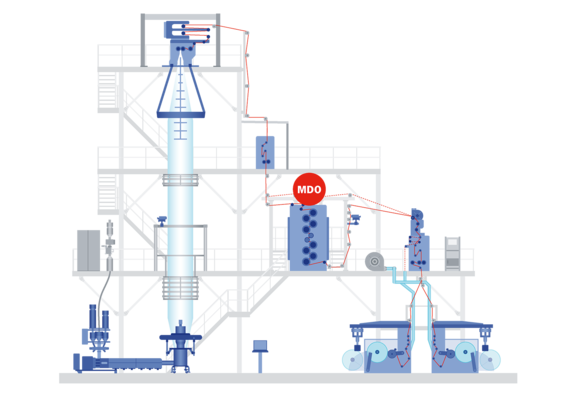

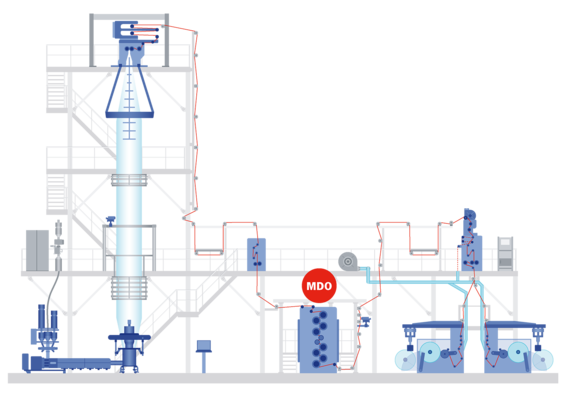

- With over 25 years of experience in monoaxial stretching, we are the pioneers in MDO technology

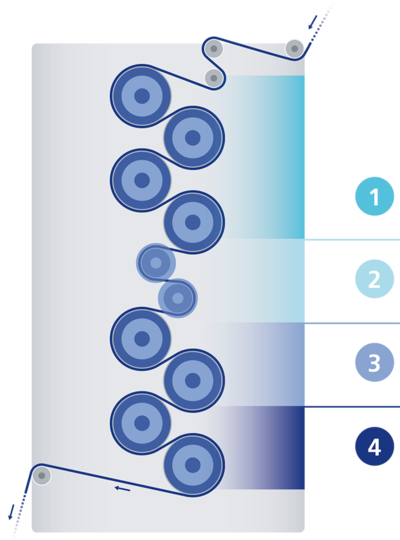

- The one-of-a-kind TRIO technology “Trim Reduction for Inline Orientation” provides significant material savings in edge trimming

- Superior MDO film quality with outstanding processability, optimized flatness and no hanging edges thanks to our new vacuum technology

Produce blocked and double flat film on Hosokawa Alpine blown film lines and benefit from maximum flexibility for your production.

Our experts will be happy to advise you — contact us!