Economic production of Heavy Duty Shipping Sacks

Heavy duty shipping sacks made of plastic film are inexpensive, robust and offer proven solutions to shipping requirements. Although the sacks are mass products, they meet the highest technical requirements. They must be able to safely withstand the forces they are exposed to and meet numerous quality criteria:

- High stiffness and excellent sealing characteristics

- Dimensional stability even at higher temperatures

- High puncture resistance

- Low tear propagation

- High resistance to all stresses during filling, stacking, transport, storage and even rough handling under local conditions

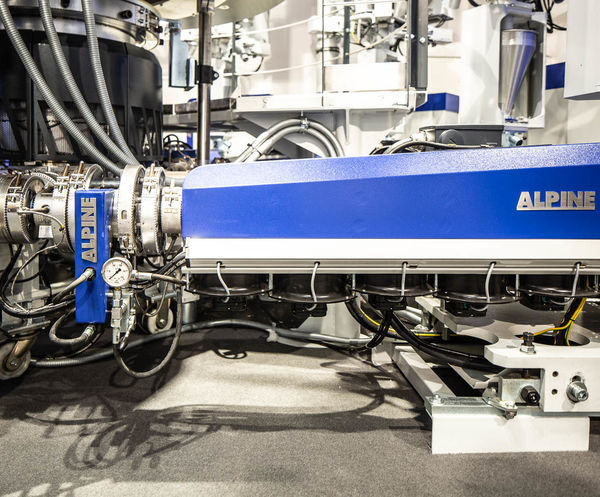

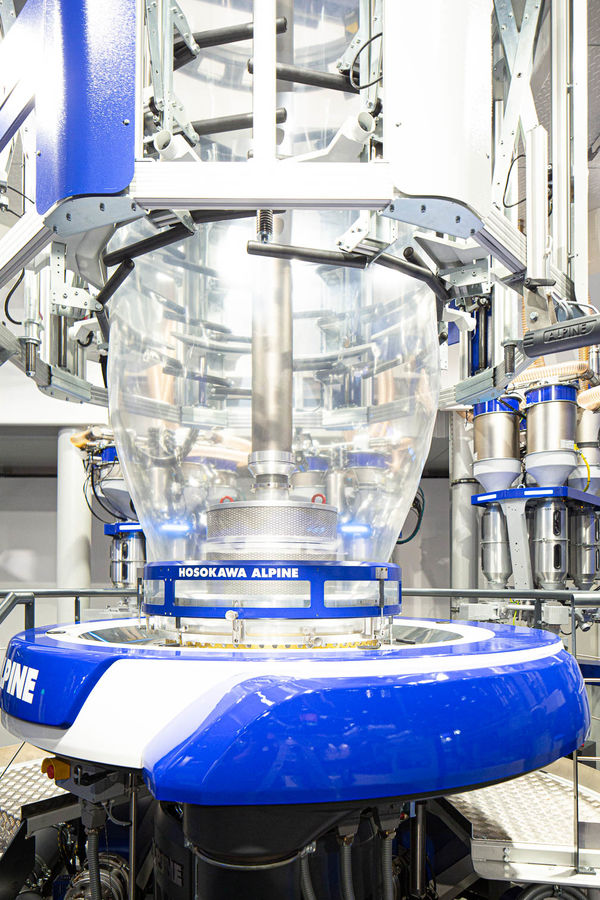

Blown film lines from Alpine

Optimized for the production of Heavy Duty Shipping SacksThe market for Form-Fill-Seal (FFS) packaging is primarily driven by productivity and efficiency. Hosokawa Alpine's heavy duty shipping sack lines are customized for the formulations and dimensions required to produce heavy duty shipping sacks. This dedicated concept combines

- very high output rates with

- excellent thickness tolerance and

- high reel quality.

The films are further processed on FFS lines designed to produce heavy duty shipping sacks. To this end, the film is fed from a reel as a side gusseted tube. The film tube can either be made directly on the blown film line or be produced by means of a longitudinal welding process from single sheet film made on the blown film line.

We are the experts:

- More than 25 years of experience in project planning and production of heavy-duty shipping sack lines

- More than 100 Hosokawa Alpine heavy-duty shipping sack systems are in use worldwide

Your advantages

- Specially developed line for FFS applications

- Highest output with low energy consumption through compact extrusion

- Alpine lines are very flexible and designed for a wide range of raw materials and viscosities

- Best thickness tolerances and shortest purging times

- Screws designed for low shear and low temperature

- The modular design allows the subsequent conversion from 3-layer to 5-layer designs

- Optional from Hosokawa Alpine: Dual use lines that allow the production of both heavy duty shipping sack films and stretch hood films

Technical details

- Optimized screw design for controlled melt temperature

- Die head: Alpine X-Die (minimum residence time and low pressure)

- Die diameter: 160 mm or 180 mm

- Layflat: max. 800 mm

- Number of layers: 3/5

- Extruder Screw diameter: 50 mm, 65 mm, 75 mm

- Raw material: mLLDPE, LDPE, HDPE + additiv and masterbatch white

- Alpine internal cooling with unique parrafin collection

- Single winderr: WS8 for heavy duty shipping sacks, reel diameter up to 1,500 mm

- Installation height: appr. 17 m

- Optional: inline and offline printing unit with 4/6 colours

- Optional: gusetting und embossing tower